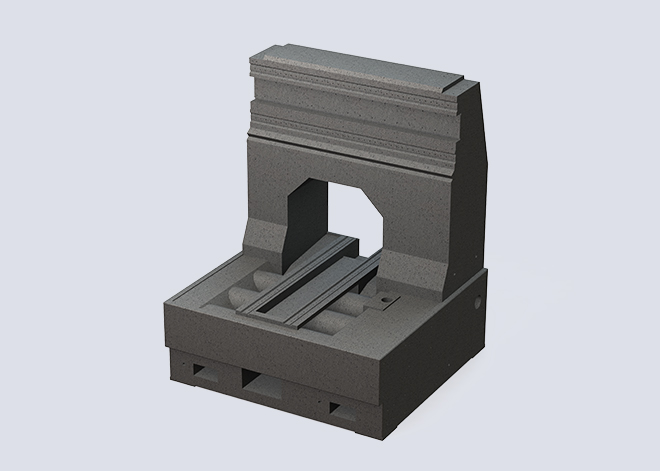

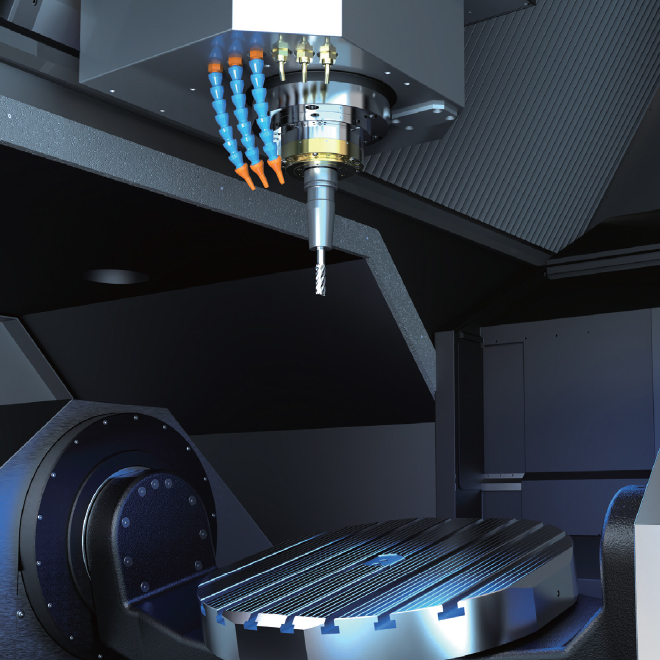

Polymer concrete main frame

Blocking Heat in heating area and Suppressing Vibration during High Speed Processing, is essential for High-Precision. The Main frame of the machine is Polymer Concrete, which has a vibration damping effect that is ten times more effective than cast iron and has an effect of suppressing heat conduction.