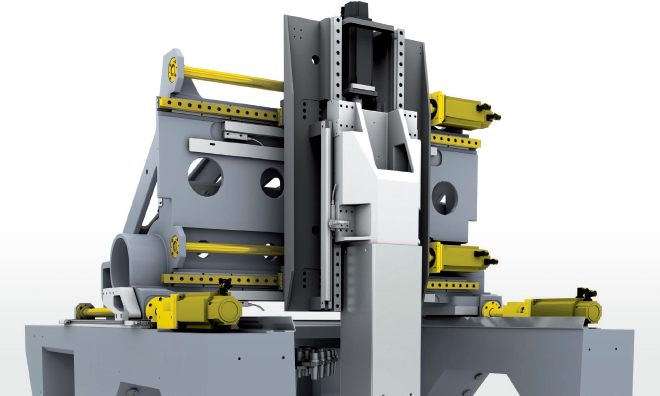

Dual Gantry drive

Highly dynamic dual drives optimise the force application points and thereby create the best conditions to actively eliminate unevenly distributed applications of force and vibrations.

Highly dynamic dual drives optimise the force application points and thereby create the best conditions to actively eliminate unevenly distributed applications of force and vibrations.

From HSK E40 / HSK E50 to HSK A63.

All spindles are optionally available with internal coolant supply. The following types of media can be used: air, water or aerosol - an unique cutting medium for very low consumption.

Minimal path deviations and perfect vibration damping result in the highest surface quality and a long cutting tool life.

Maximum capacity! Integrated in the machine bed, it takes up minimal space! An external changer is optionally available for tool capacities of up to 175 positions. It can also be designed as a combined workpiece and tool changer.

800 * 600 * 500 (mm)

max. 2,000 kg

Ø600 mm / H = 550 mm

max. 500 kg

| Travel distances (X*Y*Z) | 800 * 600 * 500 (mm) |

|---|---|

| Travel speed | max. 30 m/min |

| Acceleration | max. 15 ㎨ |

| Table clamping surface | 1,000 * 660 (mm) |

| Max. T-slot table load capacity | up to 2,000kg |

| Table | T-slot table expandable over 4th/5th axis |

| T-slot | 5 * 18 H12 |

| Distance between HSK-spindle nose and table, min./max. | 70 / 570 mm (175 / 675 mm*) |

| Workpiece size 3-axis X/Y/Z | 800 * 600 * 500 mm (max. 2,000 kg) |

| Workpiece size 5-axis | Ø600 mm / H = 550 mm (max. 500 kg) |

| Connected load | 32 kVA |

| High-frequency spindle selection |

|

| Spindle power | 15 kW / 17 kW / 25 kW |

| Tool changer selection |

|

| Minimum lubrication | Included |

| CNC control unit | HEIDENHAIN TNC 640 |

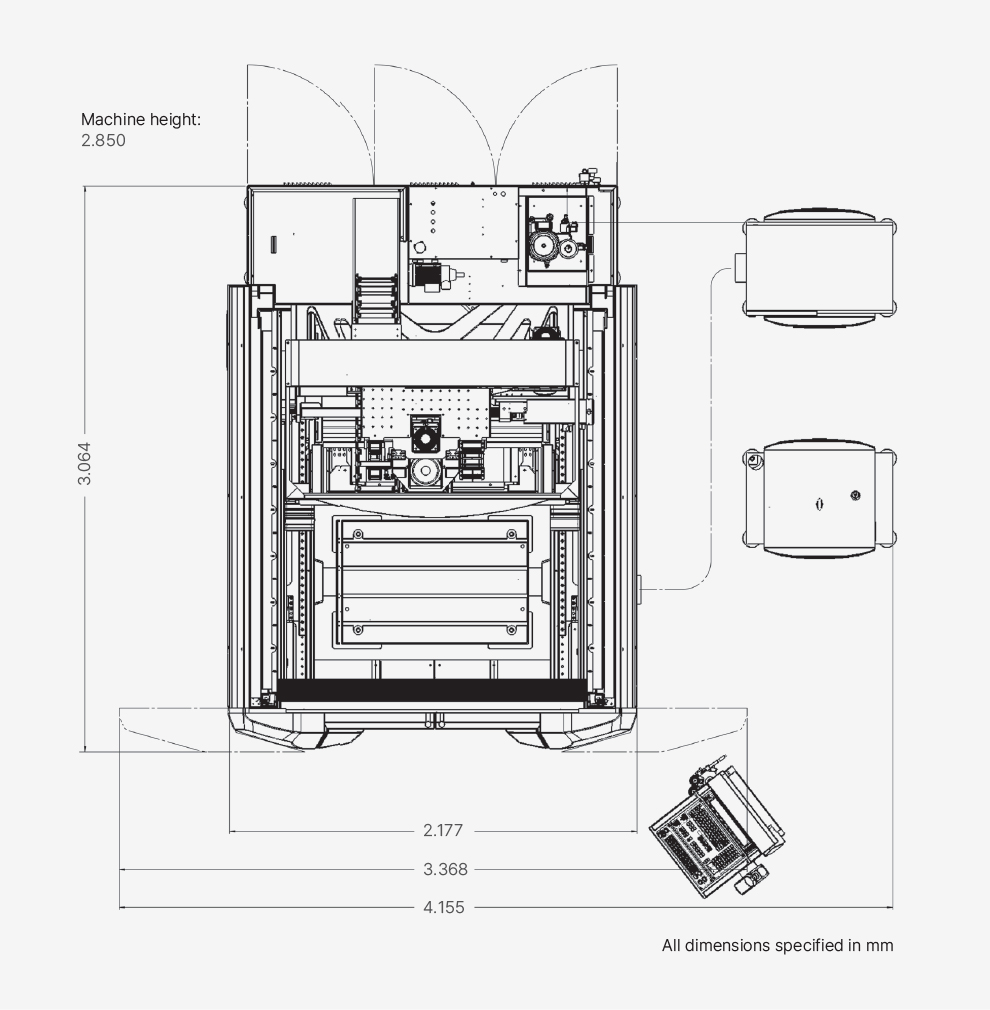

| Dimensions | 3,064 * 2,177 mm / H = 2,850 mm |

| Total weight | 11,500 kg |

| Options |

|

| Further options |

|