Even more highlights

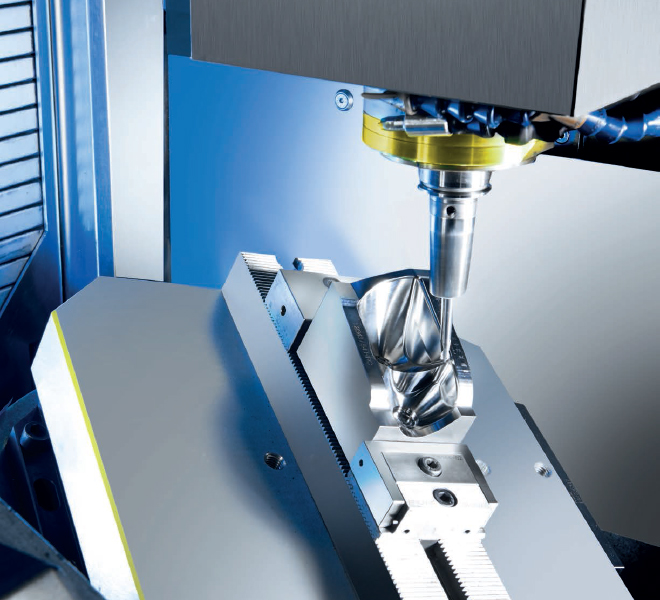

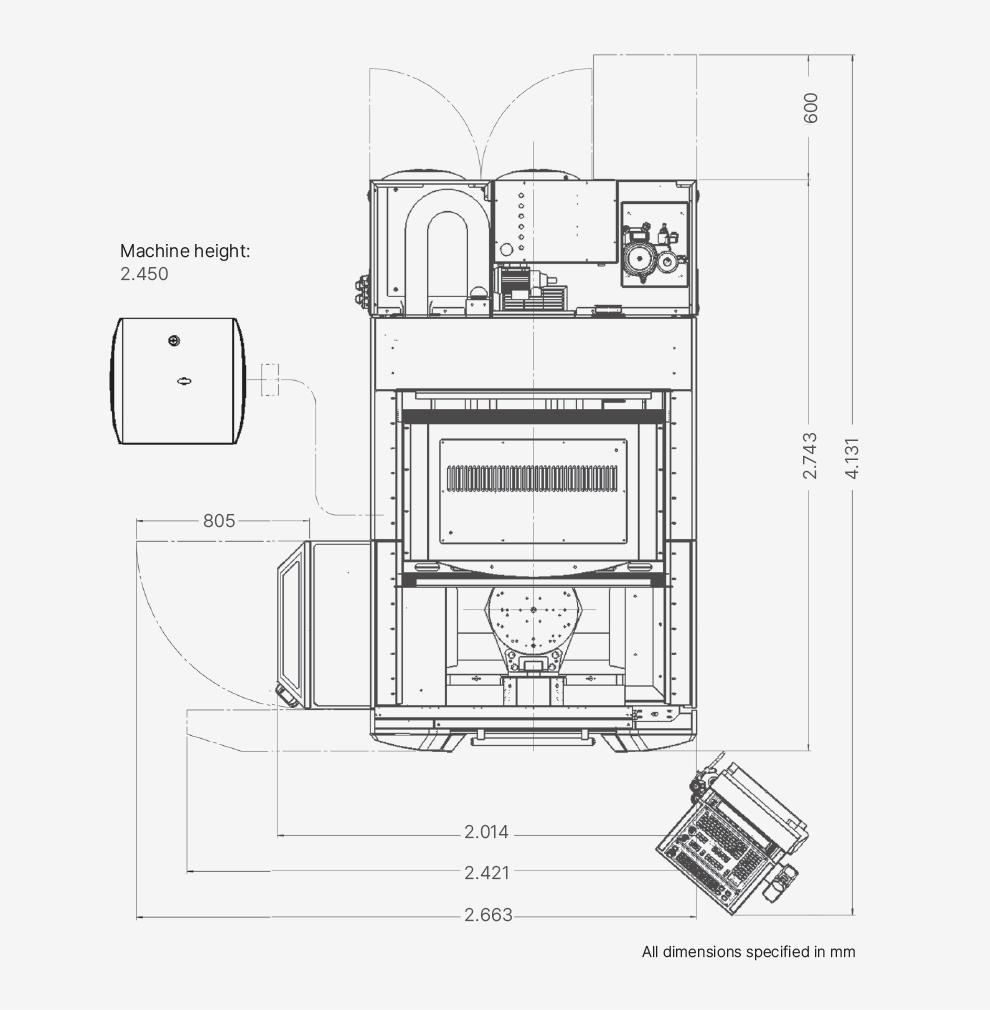

Compact size compared to maximum transport distance

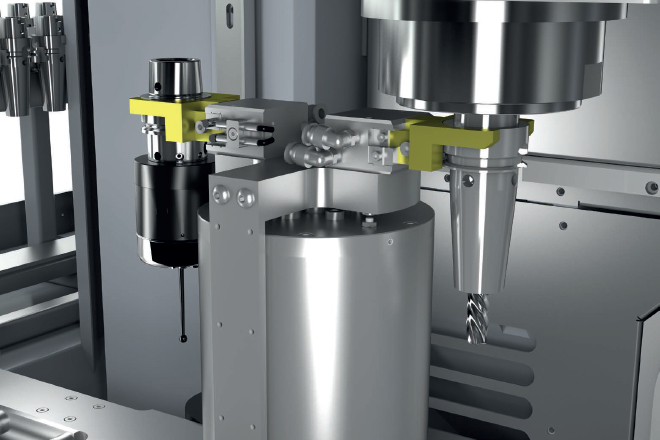

Up to 250kg with 4/5 axes using 400x400mm pallets

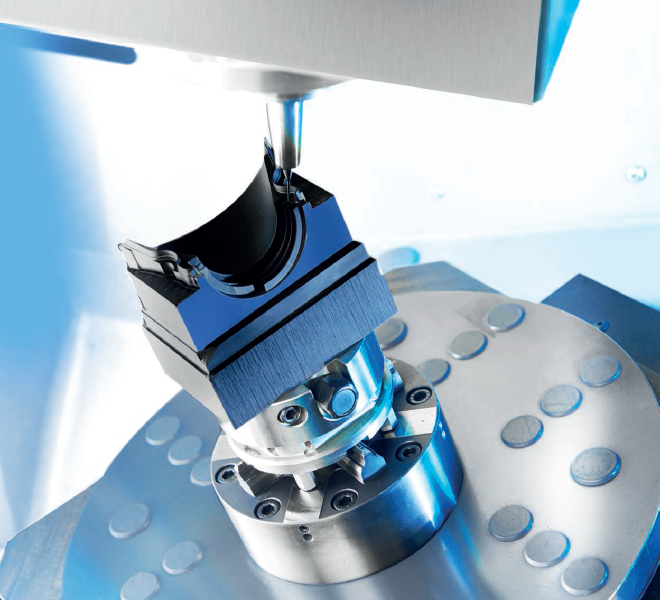

For automation and workers, accessibility is excellent.

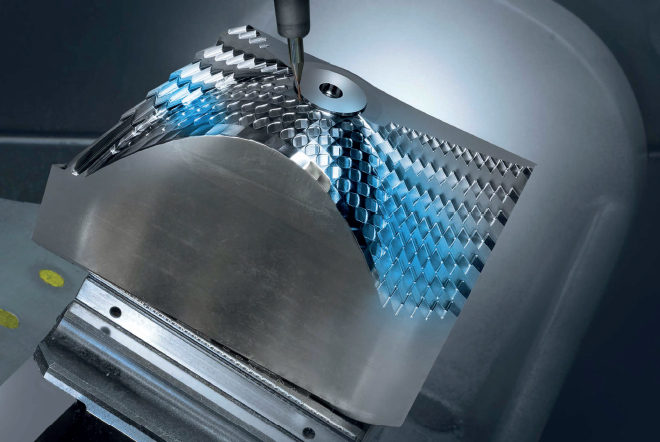

Equipped with a special protective laser measuring system.