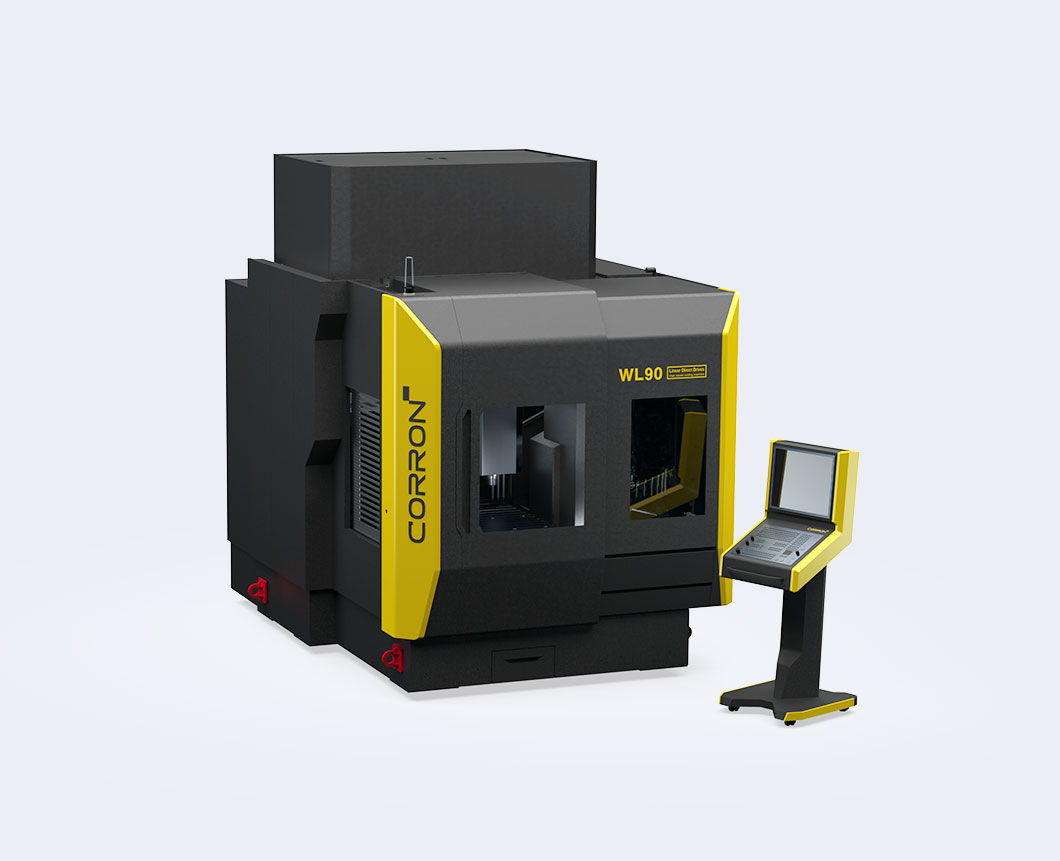

WL90

- Ultra-precision cutting of thick materials by projecting a laser onto a waterjet

- revents thermal deformation and damage to parent material due to the cooling effect of water

- Precision machining of various materials such as metal, SI, SIC, etc.

- Provides smooth cutting surface without burrs and secondary contamination

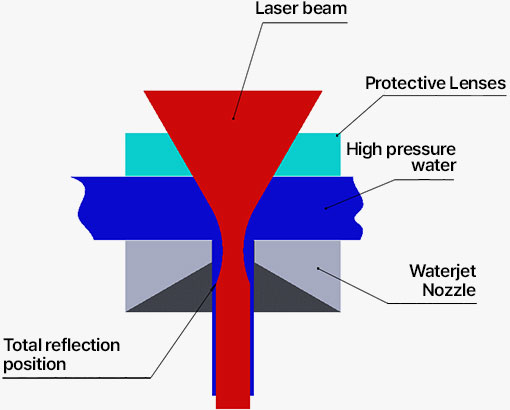

Implementation of fusion processing of laser and waterjet

Innovative fusion processing of laser and waterjet using the total reflection characteristics of light

- Fusing two technologies by coupling a laser into a waterjet

- Minimized heat affected zone (HAZ) due to water, resulting in minimal deformation

- Materials thicker than 15mm can also be processed

- Has excellent processing perpendicularity compared to traditional laser processing

- Very small slot machining down to 0.06 mm is possible

- Processable depth (based on 4kW)

- Si < 12T- SiC < 8T- Al < 18T- Steel < 10T

APPLICATIONS

-

Sample 1

Sample 1

Ultra High Temperature Ceramics (UHTC)

Components for semiconductor heater equipment -

Sample 2

Sample 2

SiC material

Cutting and grooving of semiconductor equipment jig parts -

Sample 3

Sample 3

SUS304 0.2T material

Semiconductor equipment components -

Sample 4

Sample 4

Al 6063 0.1T material

Ø0.06 ~ Ø0.3 hole processing test sample -

Sample 5

Sample 5

SUS304 3T material

Semiconductor equipment parts minimum slotting width 0.06mm -

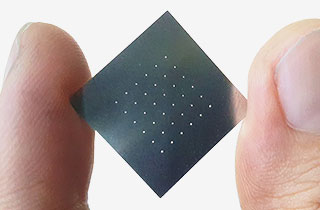

Sample 6

Sample 6

Si 4T material

Semiconductor CSR parts slotting processing sample

Technical data

| Travel distances (X*Y*Z) | 400 * 300 * 280 (mm) |

|---|---|

| B-axis rotation angle | ±105° |

| C-axis rotation angle | endless |

| Machine table 3-axis | 450 * 350 (mm) |

| Machine table 5-axis | Ø220 |

| 3-axis table loading weight | 110kg |

| 5-axis table loading weight | 70kg |

| Dimension (W*D*H) | 1990 * 2215 * 2470 (mm) |

| Controller | HEIDENHAIN TNC 640 or Siemens 840D |

| Laser head | Wavelength : 1064 - 1080 nm / Nozzle : Ø 0.05 mm |

| Water pump (water pressure) | Max. 500 bar |

| Travel distances (X*Y*Z) | 640 * 400(250) * 400 (mm) |

|---|---|

| Machine table 3-axis | 600 * 540 (mm) |

| Machine table 5-axis | Ø450 |

| 3-axis table loading weight | 650kg |

| 5-axis table loading weight | 120kg |

| Dimension (W*D*H) | 1990 * 2215 * 2470 (mm) |

| Controller | HEIDENHAIN TNC 640 or Siemens 840D |

| Laser head | Wavelength : 1064 - 1080 nm / Nozzle : Ø 0.05 mm |

| Water pump (water pressure) | Max. 500 bar |

| Travel distances (X*Y*Z) | 900 * 900(700) * 540 (mm) |

|---|---|

| Machine table 3-axis | 950 * 920 (mm) |

| Machine table 5-axis | Ø650 |

| 3-axis table loading weight | 1000kg |

| 5-axis table loading weight | 180kg |

| Dimension (W*D*H) | 2525 * 3350 * 3300 (mm) |

| Controller | HEIDENHAIN TNC 640 or Siemens 840D |

| Laser head | Wavelength : 1064 - 1080 nm / Nozzle : Ø 0.05 mm |

| Water pump (water pressure) | Max. 500 bar |

| Travel distances (X*Y*Z) | 1500 * 800 * 400(540) (mm) |

|---|---|

| Machine table 3-axis | 1540 * 850 (mm) |

| 3-axis table loading weight | 2000kg |

| Dimension (W*D*H) | 2950 * 3040 * 2950 (mm) |

| Controller | HEIDENHAIN TNC 640 or Siemens 840D |

| Laser head | Wavelength : 1064 - 1080 nm / Nozzle : Ø 0.05 mm |

| Water pump (water pressure) | Max. 500 bar |